Stock Entry Purpose

Stock Entry Purpose

A stock transaction known as a stock entry can be used for a variety of things. Learn more below about each stock entry purpose.

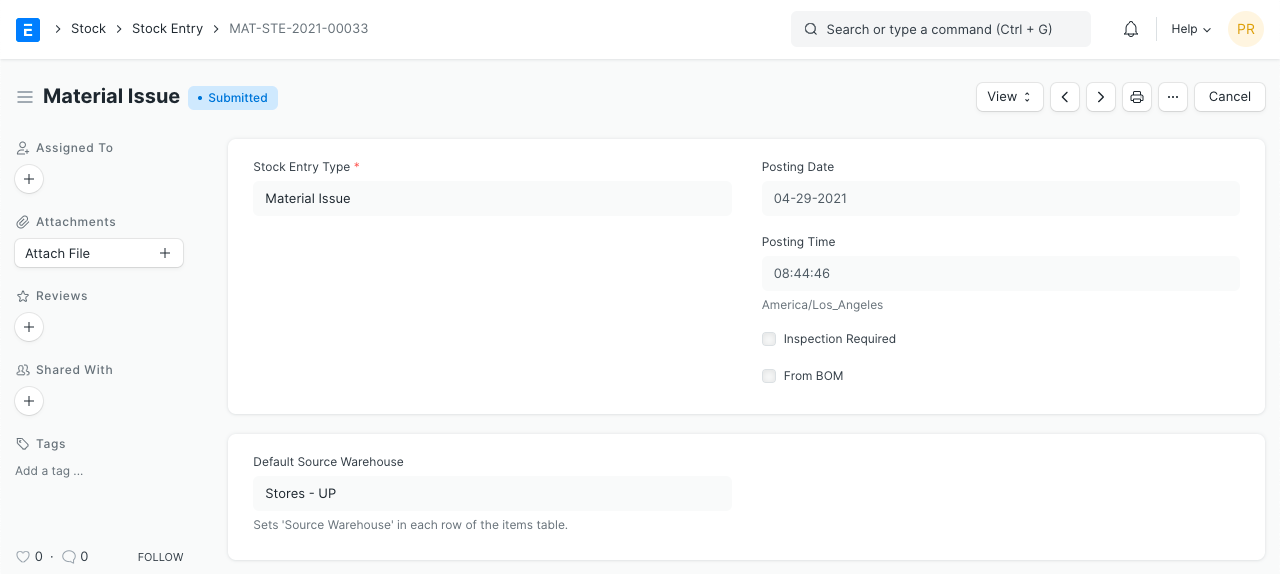

1.Purpose: Material Issue

To release item(s) from a warehouse, a material issue entry must be created. The stock of the item is taken out of the source warehouse upon submission of the material issue.

Typically, material issues are made for low-value consumables like office supplies, product consumables, etc. To reconcile the stock of serialized and batch-produced items, you can also generate a material issue.

2.Purpose: Material Receipt

To receive stock of an item or items at a warehouse, a material receipt entry is made. For the purpose of updating the opening balance of serialized and batched items, this type of stock entry can be made. From the material receipt record, products that were purchased without a Purchase Order can also be forwarded.

If Item Value becomes a required field in the Material Receipt item, it will be used for stock valuation purposes.

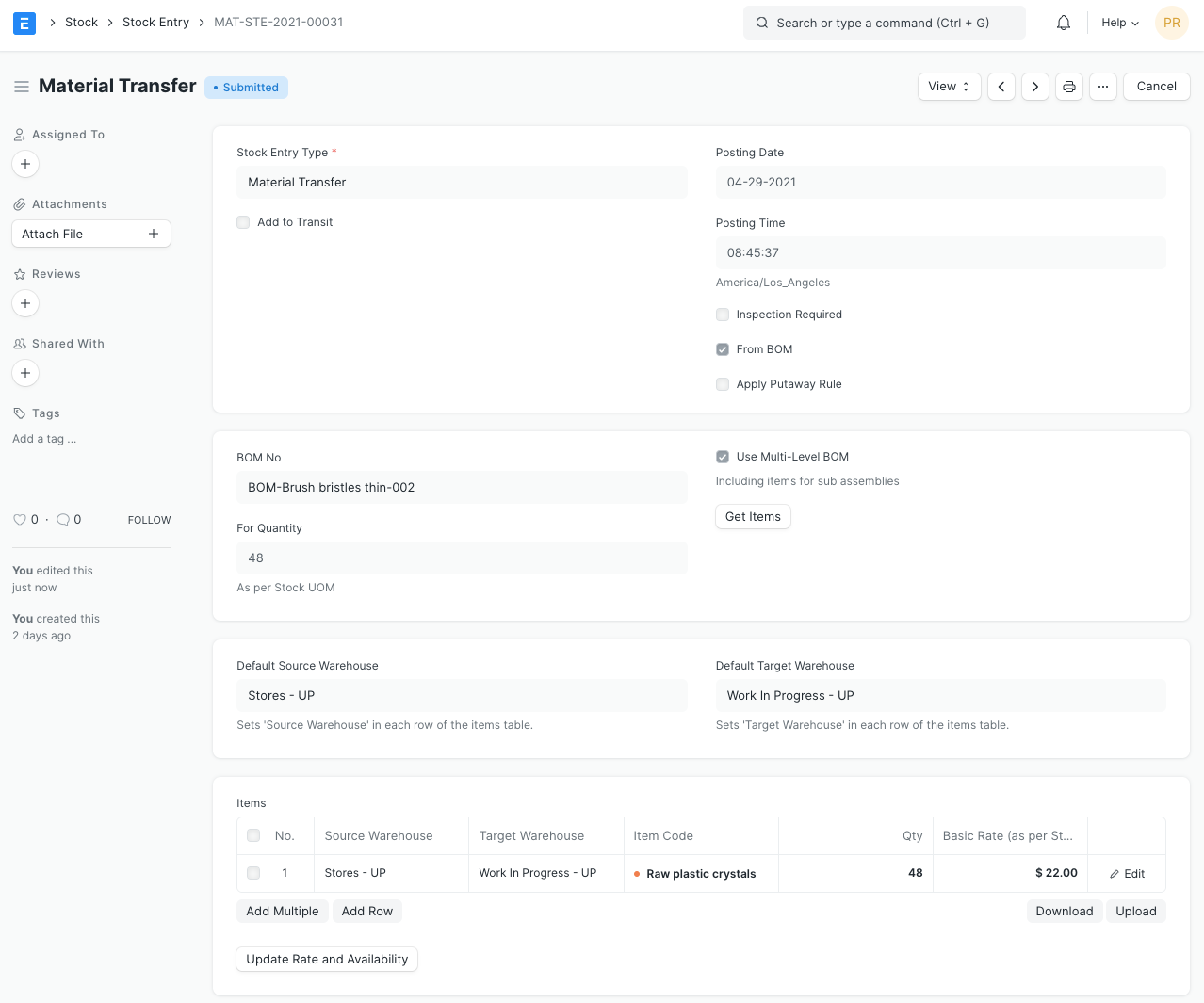

3.Purpose: Material Transfer

For the inter-warehouse Material Transfer, an entry is created.

4.Purpose: Material Transfer for Manufacture

Raw supplies are distributed from the stores to the production department during the manufacturing process (generally WIP warehouse). Work Order was used to construct this Material Transfer item. The items in this entry were pulled from the manufacturing item's BOM according to the Work Order selection.

4.Purpose: Manufacture

The production department receives raw materials from the stores for use in the manufacturing process (generally WIP warehouse). Work Order served as the basis for this Material Transfer item. Items in this entry were pulled from the Work Order's specified production item's BOM.

5.Purpose: Repack

When items purchased in bulk are repackaged into smaller packs, a Repack Entry is created. To learn more about Repack entry, see this page.

6.Purpose: Subcontract

The corporation transfers raw materials to the subcontractors' warehouse as part of a subcontracting transaction. For the subcontractor, a warehouse must also be added. Stock is moved from the company's warehouse to the subcontractor's warehouse through subcontract entry. To learn more about subcontracting, visit this link.