Quality Procedure (Standard Operating Procedure)

Quality Procedure (Standard Operating Procedure)

Introduced in Version 12

A Standard Operating Procedure (SOP) that is used as a guide to do standard tasks is known as a quality procedure.

A standard operating procedure (SOP) is a list of detailed instructions created by a company to assist its staff in carrying out everyday tasks. SOPs seek to minimize misunderstandings and failure to adhere to industry laws while increasing effectiveness, high-quality output, and consistency of performance.

There are two categories of quality procedures:

A process with clear steps that you must adhere to in order to accomplish a quality goal

a process including sub-procedures and potential independent steps

Go here: to access the list of Quality Procedures.

Home > Quality > Goal and Procedure > Quality Procedure

1. How to create a Quality Procedure

Click New under the Quality Process list.

Give the Quality Process a name.

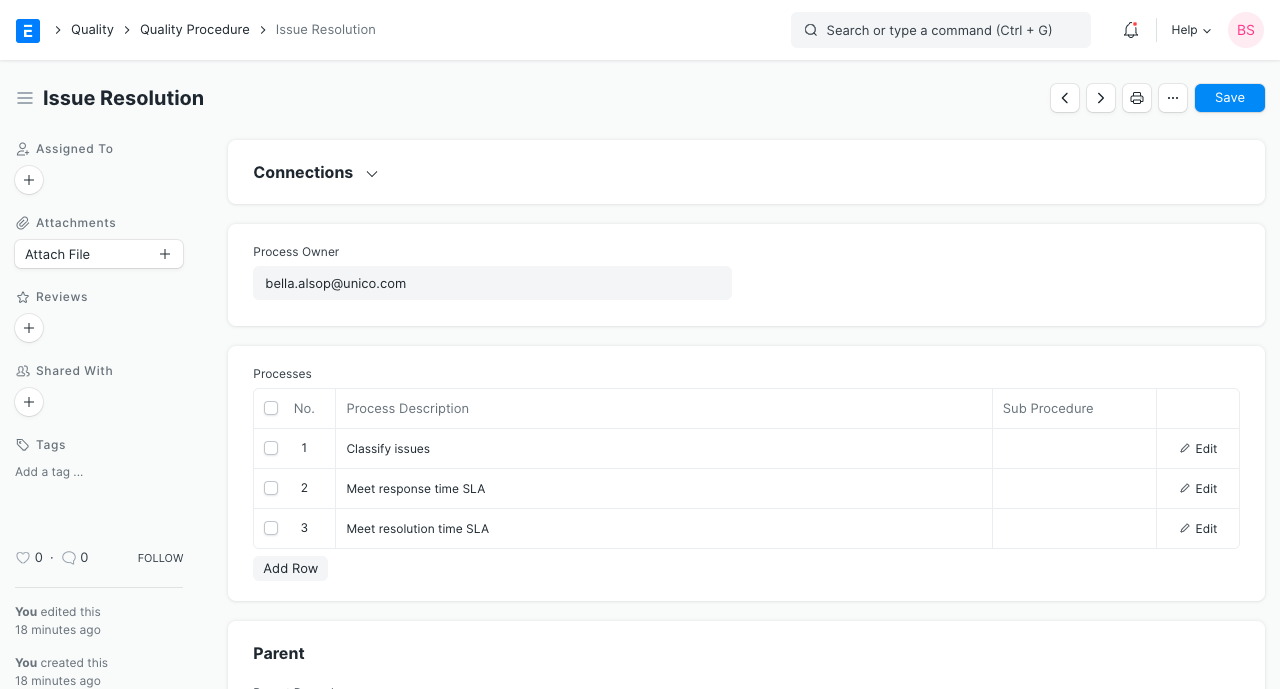

Process Descriptions should be entered in the Processes table.

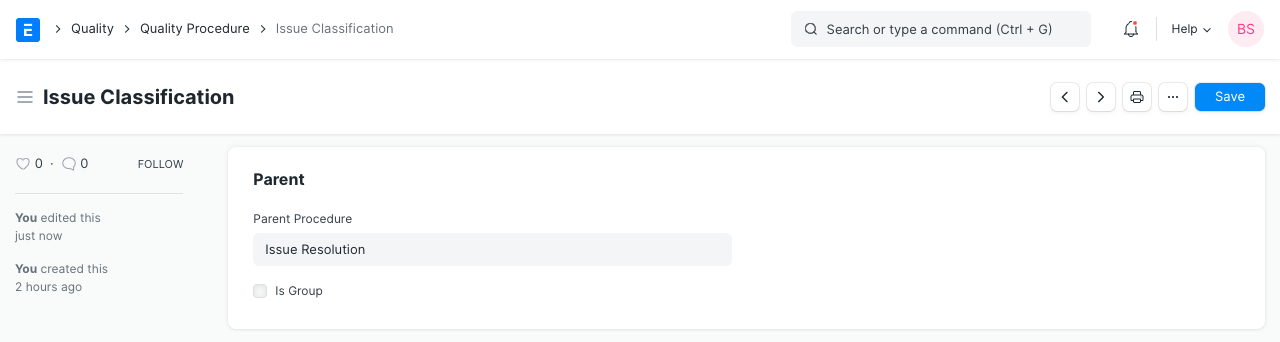

Child Procedure: Link the sub-procedure here if the Quality Process being established is a parent procedure that contains sub-procedures. By doing so, the current process is elevated to the status of a parent and the "Is Group" checkbox is turned on.

Save. If the title is self-explanatory, a quality procedure can also be stored without the process descriptions.

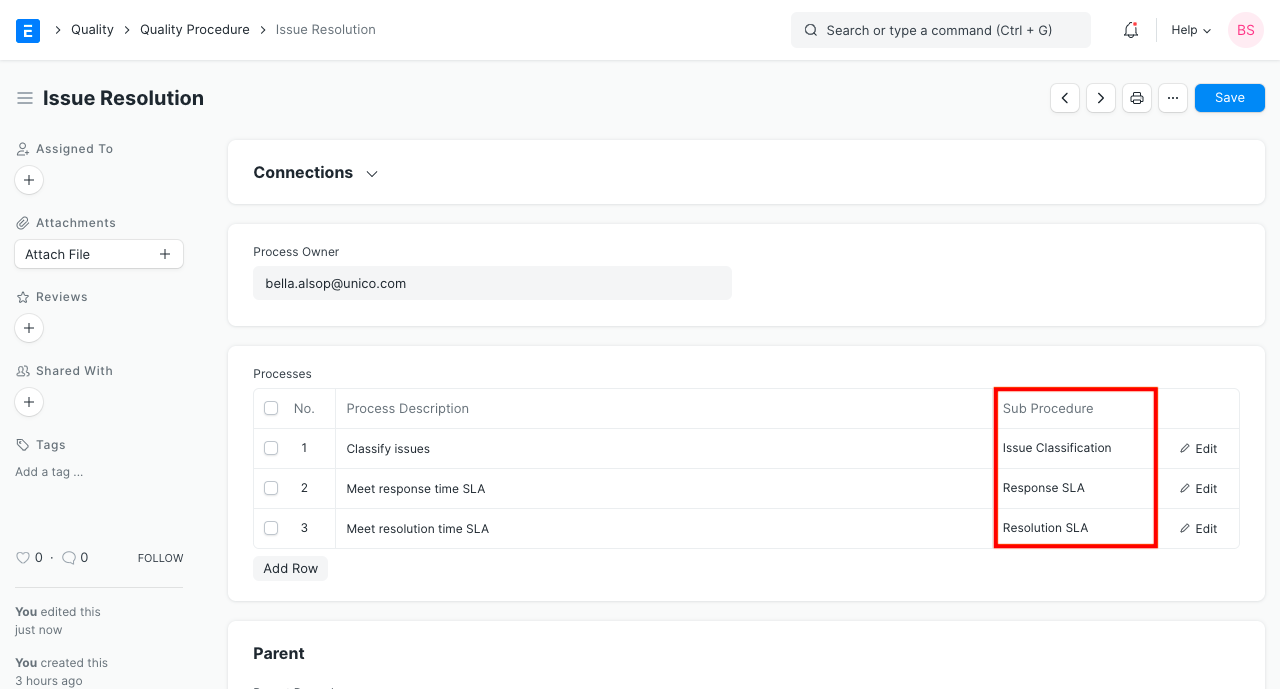

The "Child Process" is connected to the "Parent Procedure." For instance, "Issue Classification" must be completed prior to a resolution, hence "Issue Resolution" is the parent in this case:

2. Features

2.1 Using Quality Procedure in Quality Goal

A Quality Process can be used to a Quality Goal once it has been developed:

2.2 Sub Procedures

Process might be a different quality procedure or merely a set of instructions. A Quality Process can be connected to another one as a sub-procedure:

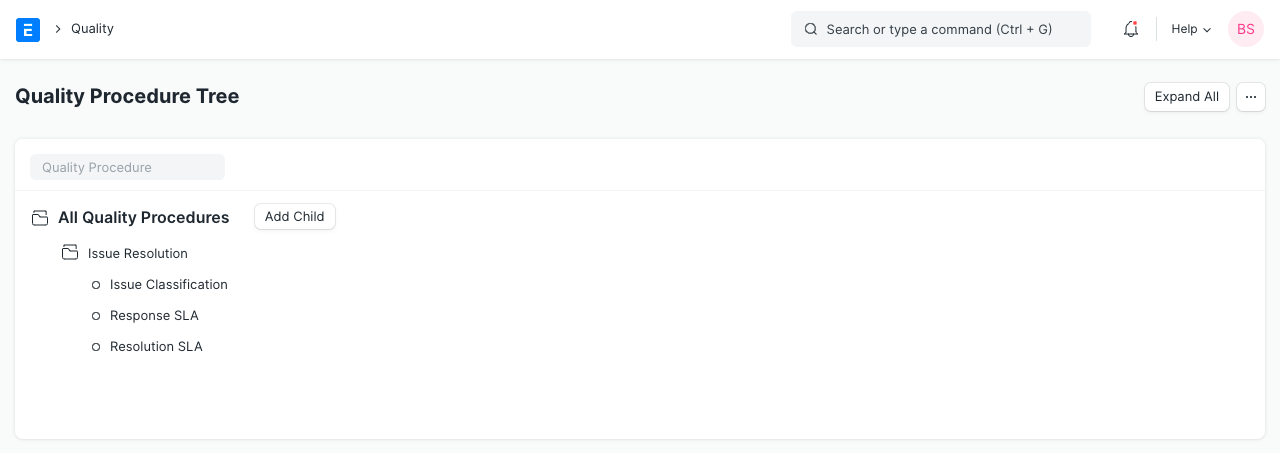

2.3 Hierarchical View

For simple organizing and navigation, Quality Processes can also be seen in a tree format.