Stock Entry

Stock Entry

You may track an item's movement across warehouses using a stock entry.

Go to: to access the Stock Entry list.

Home > Stock > Stock Transactions > Stock Entry

The following uses are permitted for stock entries:

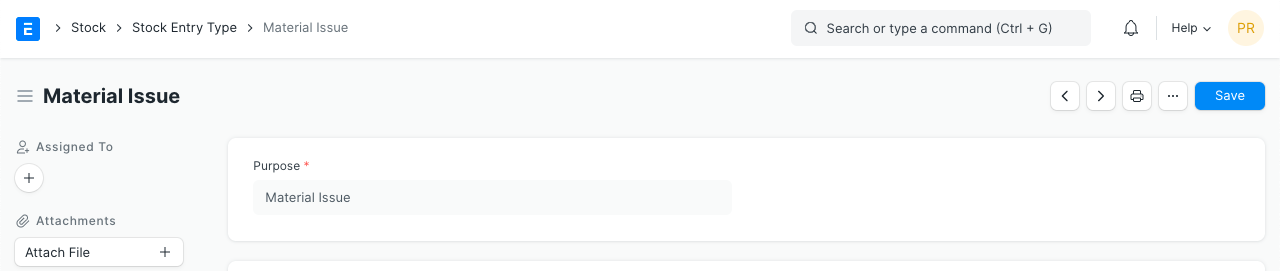

Material Issue: Whether the information is being distributed internally or externally (Outgoing Material). The Warehouse designated under Source Warehouse will be emptied of the Items.

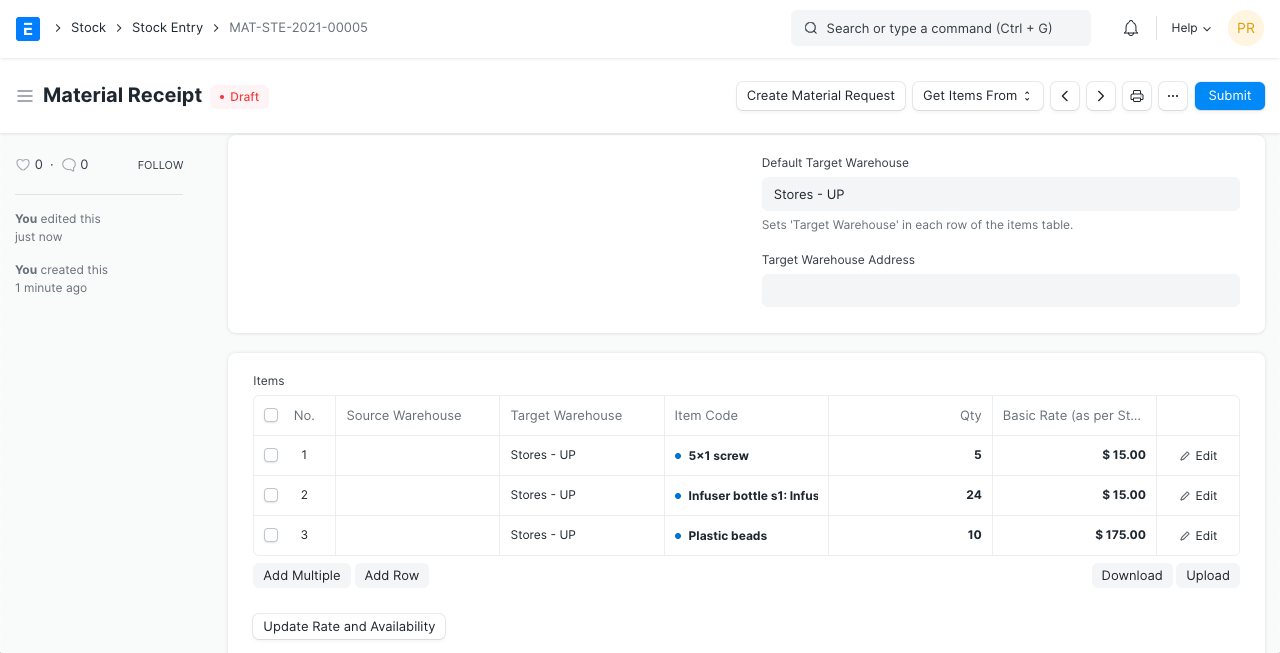

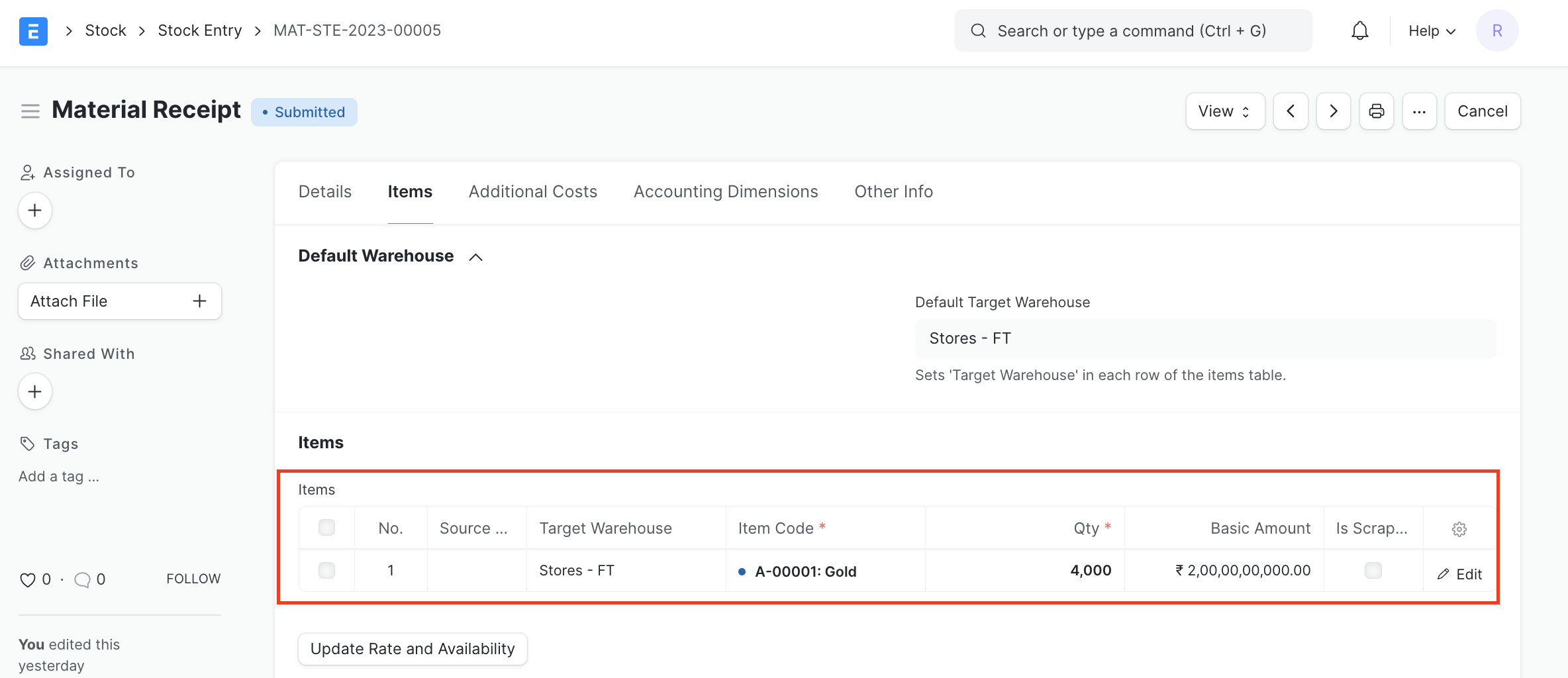

Material Receipt: Whether the information is being received (Incoming Material). The Warehouse set under Target Warehouse will get the Goods.

Material Transfer: If the material is being transferred between internal warehouses.

Material Transfer for Manufacturing: if manufacturing requires the transfer of raw materials. The move may be made in response to a Job Card or Work Order. Visit the Bill Of Materials page to learn more.

Material Consumption for Manufacture: Several consumption stock entries may be made in opposition to a manufacturing Work Order. See this website for further information.

Manufacture: if a manufacturing or production operation is providing the material. Repack: When the original object or items are placed within a new item or items.

Send to Subcontractor: if the material is being used for a task under a separate contract. A purchase order is the source of this record. Visit the subcontracting page to learn more.

Visit this page to learn more about the various stock entry types in detail.

1. Prerequisites

It is suggested that you first create the following before creating and using a stock entry:

- Warehouse

- Item

2. How to create a Stock Entry

Work Orders are typically used as the starting point for creating stock entries for manufacturing. Use these steps to manually establish a stock entry for another use:

Click New from the Stock Entry list.

From the options above, pick Stock Entry Reason.

The rows in the Items table will have the Default Source and Target Warehouses filled up automatically if you set them.

In accordance with the Stock Entry Purpose you chose, Source/Target Warehouses will be accessible.

Enter a quantity after choosing Items.

The amount will be calculated automatically after retrieving the base rate.

Publish and save.

2.1 Additional options when creating a Stock Entry

Work Order: This area will display the Work Order if the submission is for manufacturing.

Edit Posting Date and Time: will let you change the time and date of the stock entry.

Inspection Required: If the Items require a Quality Check before the Stock Entry may be submitted.

From BOM: The corresponding BOM for the item being manufactured will be displayed if this is a Manufacturing entry.

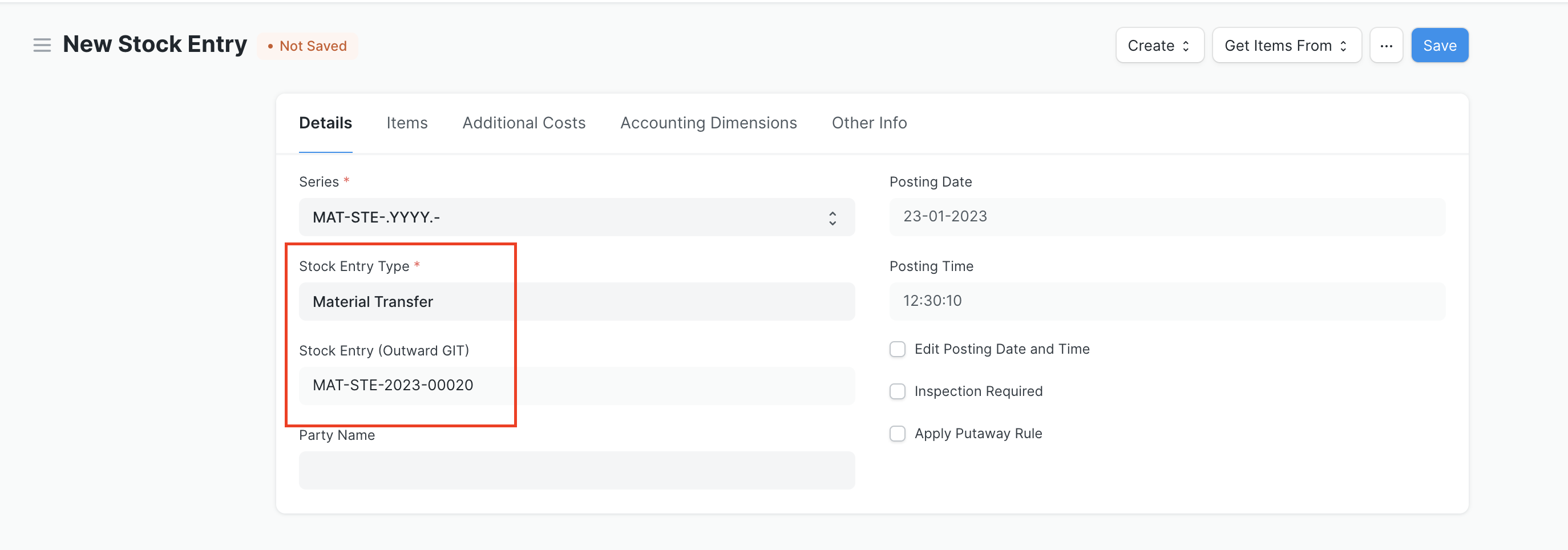

2.2 Stock Entry Type

You can also establish a Stock Entry Type with just a name change, such as "Scrap Entry." Although the name will be changed, the goal will still be material transfer. This is helpful if you only want particular Users to be able to perform certain stock-related operations.

3. Features

3.1 The Items table

Here, information regarding the Item, Rate, Quantity, etc., will be displayed.

By selecting "Accept Zero Valuation Rate," you can submit the purchase receipt even if the item has a zero valuation rate. This may be a result of a mutual understanding with your Supplier or a sample item.

For certain items, various Source and Target Warehouses can be set.

3.2 Scrap and Process Loss

Scrap Item: By-products, such as scrap, can be treated as products. The scrap goods will be added to the scrap warehouse with the valuation rate. Under the Basic Rate section, users can manually set the valuation rate for the junk item.

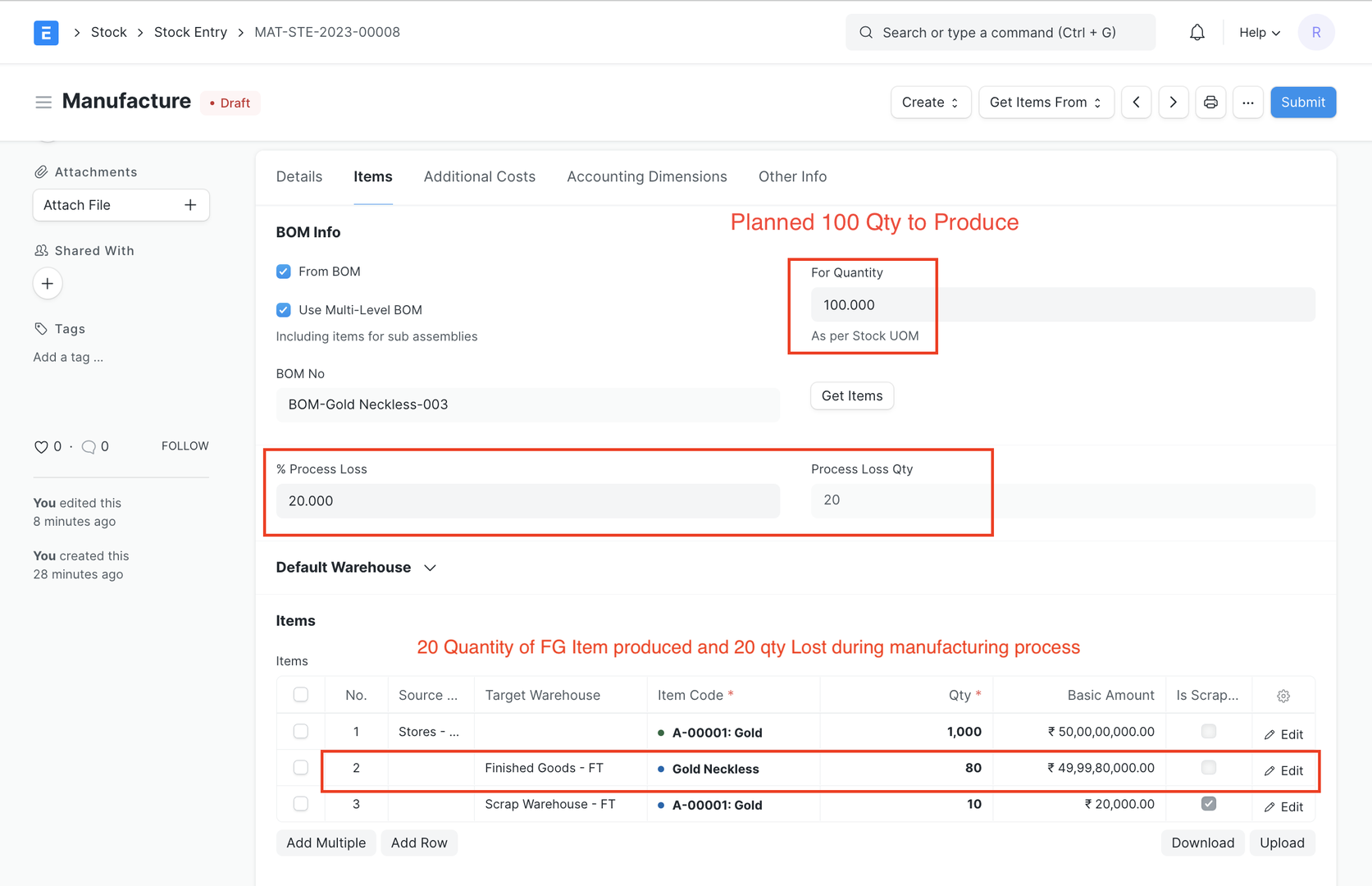

Process Loss: Process Loss will result in fewer FG Items, but it has no effect on the stock. In the image below, the user had intended to create 100 FG items, but only 80 were created during the manufacturing process. The user has used all of the raw material quantities to create 80 FG Items. As 20 quantities were produced in this instance, the system has designated them as Process Loss Qty. The 80 quantities of the FG Item have the 20 quantity process loss cost added to them.

3.3 Additional Costs

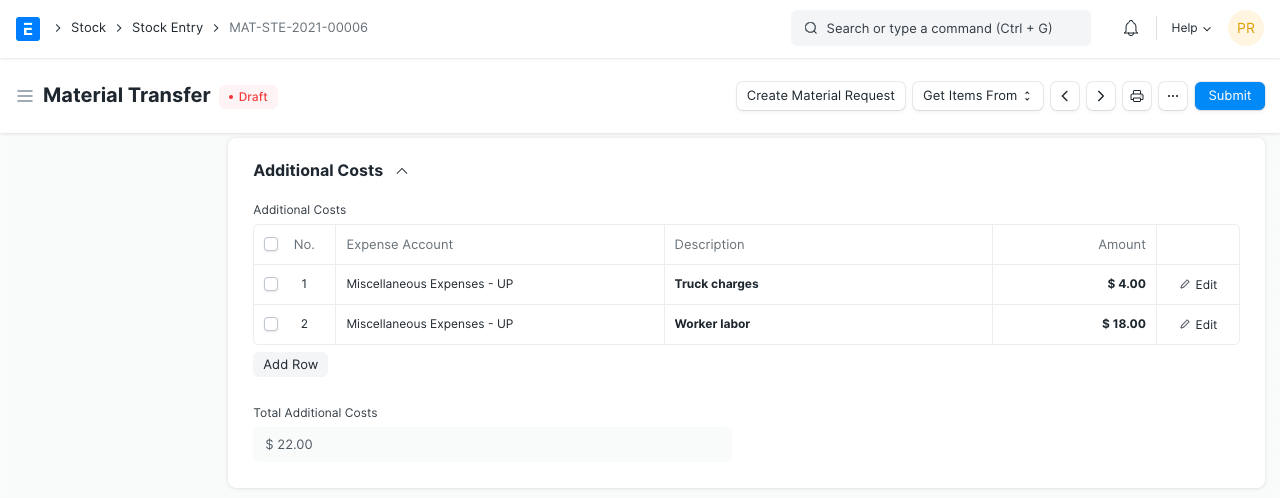

You can include additional charges connected to the process (such shipping fees, customs duties, operating costs, etc.) if the stock entry is an incoming entry, meaning any item is being received at the target warehouse. The additional expenses will be taken into account when determining the items' valuation rate.

To increase prices further:

The expense from this stock entry will be recorded to the chosen expense account.

Under the Additional Costs table, enter the cost's description and total.

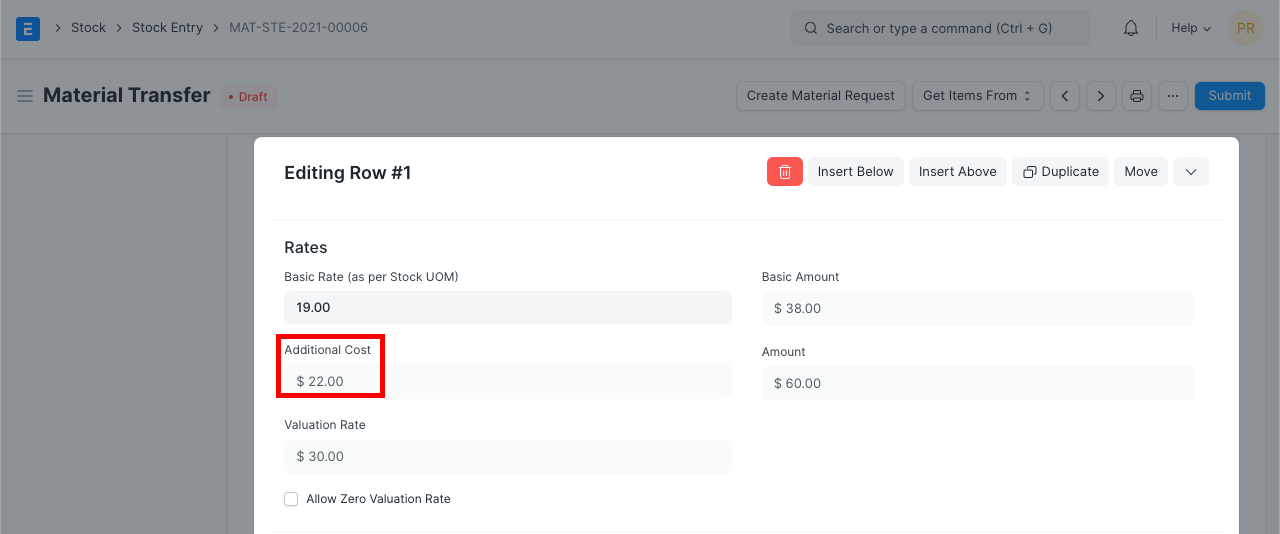

The receiving items (where the Target Warehouse indicated) will share the additional costs proportionately according to the basic amount of the items. To determine the item's valuation rate, the dispersed additional cost will be applied to the basic rate.

When you expand the Items table, Quantity and Rate are displayed as shown below.

3.4 Accounting Dimensions

Many transactions can be tagged depending on various dimensions. Although tracking the expenditures of many projects is a standard practice, Projects can be thought of as a dimension by default. Visit this page to learn more about Accounting Dimensions.

3.5 Printing Settings

Letterhead

Your purchase receipt can be printed on the letterhead for your business. Find out more here.

Print Headings

When printing the document, you can also alter the heads on the purchase receipt. This can be accomplished by choosing a Print Heading. Go to Home > Settings > Printing > Print Heading to add new print headings. Find out more here.

3.6 More Information

- Is Opening: If the opening stock entry for the Items is this one.

- Remarks: Any further comments on the item.

- Percentage Transferred: Depending on the goal of stock entry, the percentage of items moved.

- Total Amount: The total number of transferred items.

3.7 Perpetual Inventory

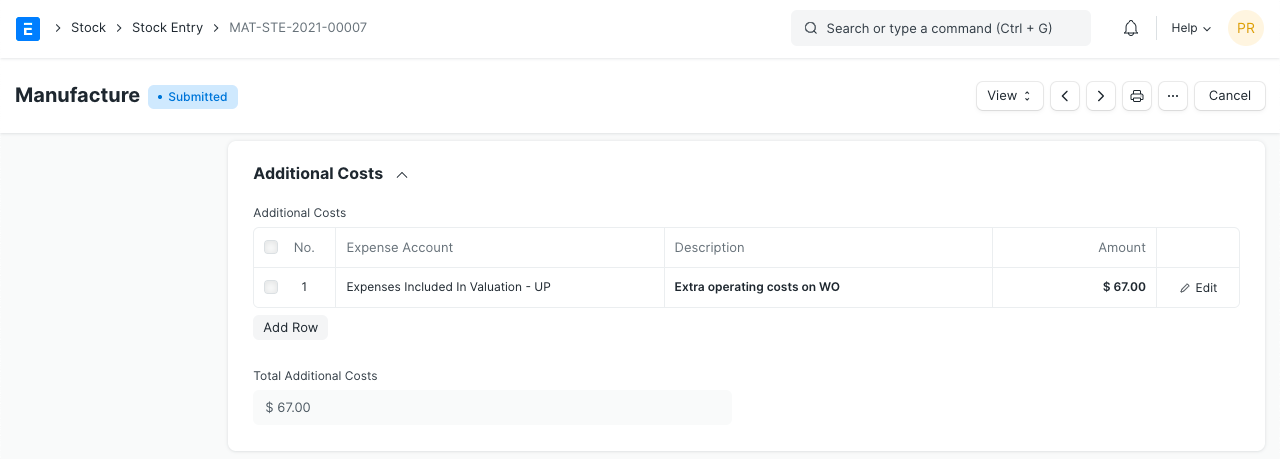

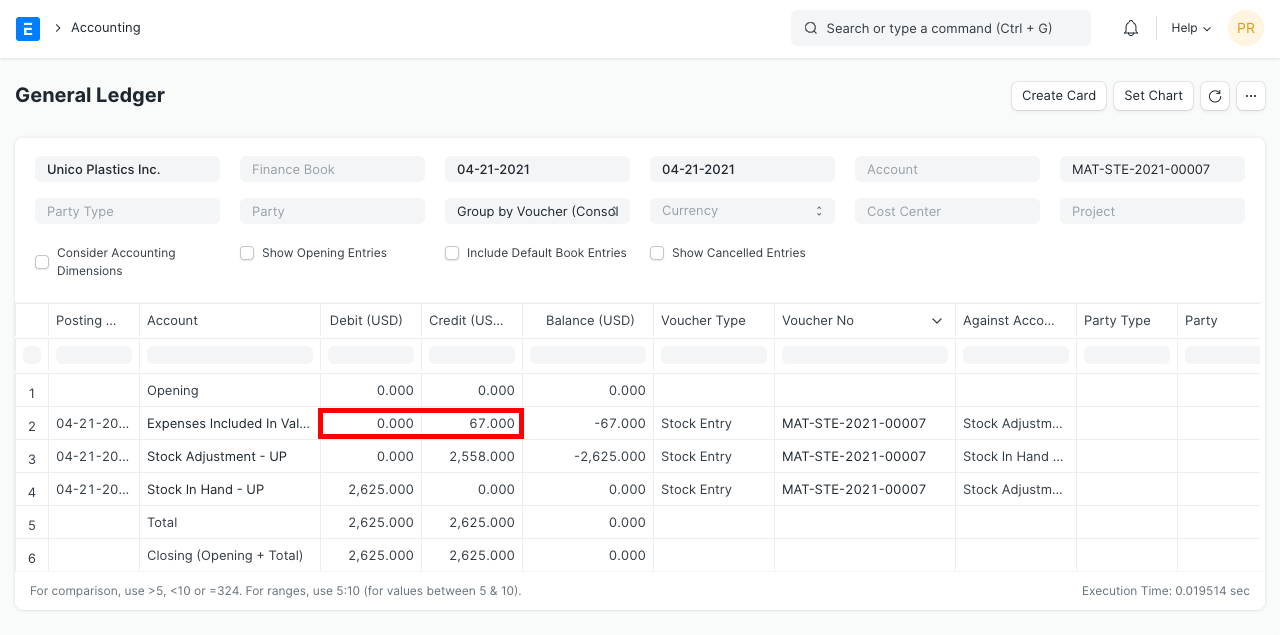

If the perpetual inventory system is enabled, the expense account listed in the Extra Costs table will be used to record additional expenses.

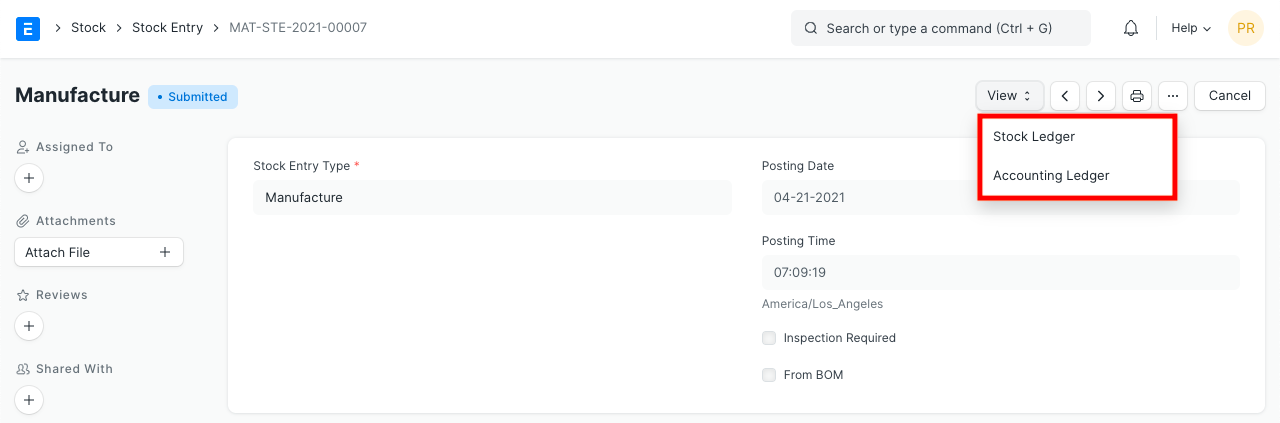

3.8 After Submitting

You can access the stock ledger or the accounting ledger from the dashboard after submitting a stock entry.

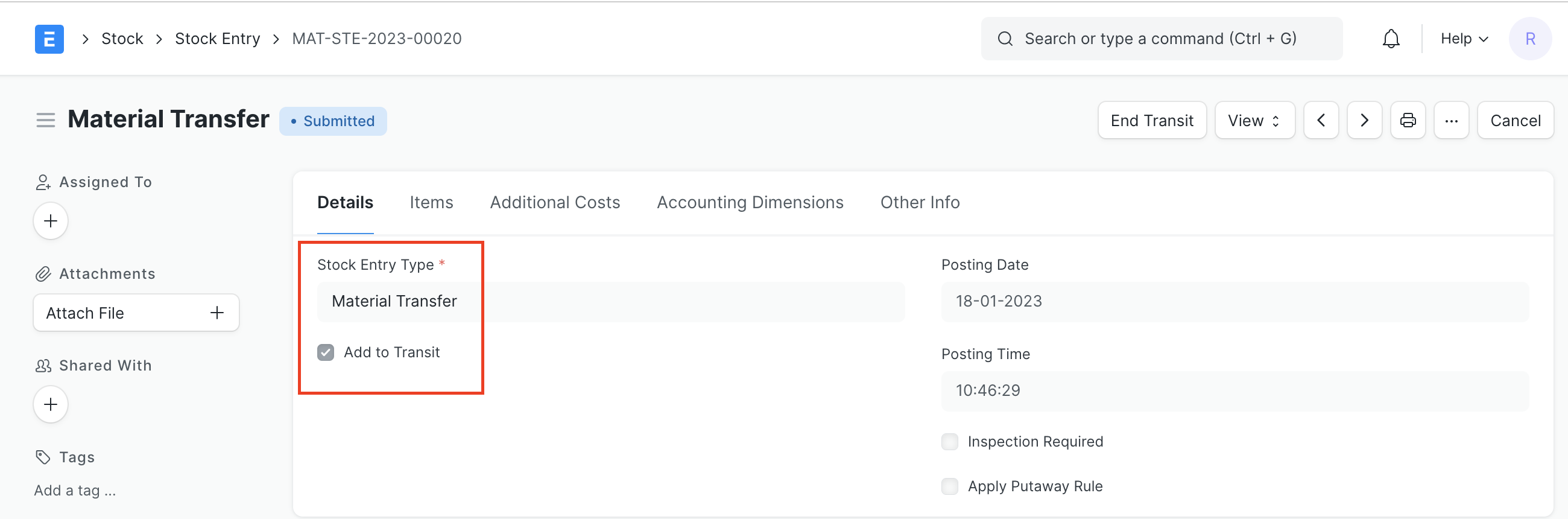

4. Add to Transit

Use the "Add to Transit" tool if you need to make two entries to transfer materials from one warehouse to another.

Make a stock entry with the "Material Transfer" type and check the "Add to Transit" box to use the "Add to Transit" feature. The warehouse of type "Transit" in the target warehouse should then be chosen after choosing the source warehouse from which you want to issue the material. You can go to the Warehouse Master and choose the "Transit" warehouse type to create a transit warehouse. Add any products that require a transfer to the stock entry after that, then submit it.

There are two ways for users to enter additional stock at the destination warehouse. Either they may create a new stock entry and select "Get Items From" -> "Transit Stock Entry" or they can open the original stock entry and click "End Transit." The original stock entry's source warehouse (Transit warehouse) and tragedy warehouse will both be used by the system to collect items. The target warehouse must be set by the user and saved.